- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

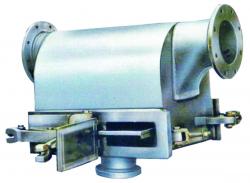

Tri Disc Deflakers for Pulp & Paper Machine

Product Code : PM-03

Brand : Parason machinery

Store Number :

2406644444

(Click to call)

Category: Industrial Plant and Machine

Price : 10.00

Parason Tri Disc Deflakers

Tri Disc Deflakers is a high speed deflaker, need primarily for deflaking a market pulp and various kinds of brokes to obtain high quality product and better strength characteristics. With Parason Tri-Disc Deflaker fibre bundles and flakes are completely deflaked into individual fibres by hydro-dynamic shock waves created with high quality deflaker discs, which rotate at a high speed of 1500 to 3000 RPM.

The freeness of the stock is slightly increased, but deflaking contributes to the uniformity of sheets and substantially improves its strength & formation.

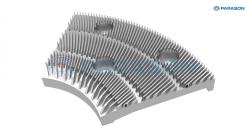

Conical Deflaker 3 Steps

Description

The construction of Rotor and stator is conical. Therefore we get more area for Deflaking in this type of Deflaker as compared to other deflekers.

The other advantages are

More output due to more area of deflaking

Power consumption is less as compared to other type of Deflekers

No load power is also less as compared to other type of Deflaker.

Get better quality of pulp

For breaking flakes in pulp

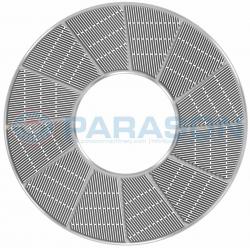

Ring Type Deflaker

Operating Principle

The pulp stock introduced centrally into the deflaker, pass through the gap between the rotor and stator and teeth of each ring towards the outlet. Unique tri disc- system, the rotating disc at high speed creates strong turbulence and hydro-dynamic stock waves and the fiber bundles and flakes while passing through the gap between teeth of rotor and stator of release the bonds between individual fiber under the impact of high frequency waves and frictions.

Depending on the furnish and required differing efficiency the outer most rings size is selected and the gap between rotor and stator is adjusted by shims.

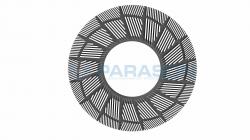

Innovative Features

The filling design is very precision with simplicity in manufacturing.

The fillings are manufactured with all over machined surface which gives better deflaking effect on the fibre.

The gap between stator and rotor disc is constant hence no clashing of stator to rotor disc in spite of fluctuations in flow or pressure of pulp.