- All Categories Display all categories

- Advertisement Ad Agencies, Marketing

- Travel Travel agents, Taxi Services, Flight, Bus Ticketing, Passport & Visa

- Hotels & Restaurants Hotels, Restaurants , Bars , Resorts, Dhaba

- Industry Company, Factory, Work shops, MNC

- Shopping Boutiques, Shop

- Real Estate PG ,Property - Shops, Malls , Flats, House, Rental

- Entertainment Cinema & Theaters, Amusement Parks, Clubs

- Education Schools , Colleges, Institutes, Coaching Centres , Universities, Books

- Medical Hospitals, Doctors, Chemists, Blood Bank, Medical Products

- Lifestyle Lifestyle, fashion, cosmetics, boutique, tailors, shoes

- Services Services, Home Services, Special Services

- Finance Financier, Banks, ATM, Loans, Insurance, Forex , Money Transfer

- Events Banquet Hall , Tent House , Auditorium, Caterers, DJ, Pandit

- Hardware Hardware Tools, Hardware Dealers,

- Listed Products

Accujet High Turbulance Head Box for Pulp & Paper Machine

Product Code : PM-012

Brand : Parason machinery

Store Number :

2406644444

(Click to call)

Category: Industrial Plant and Machine

Price : 10.00 431001.00

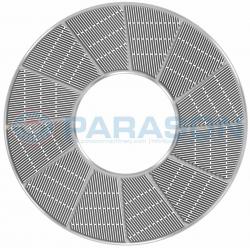

Parason Head Box & CDT

Open HeadBox With German Collaboration - Accujet High Turbulance Head Box - Pulp & Paper Machine

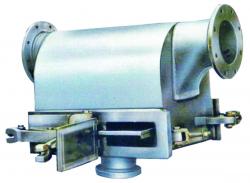

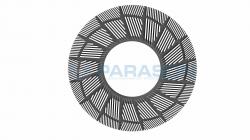

A gravity head of the stock is used to give correct discharge velocity. In other words it is adjusted by pond level. Open HeadBoxe works in lower speed. It has two rectifier or holy rolls rotating in opposite directions to create turbulence required to make the stock homogeneous.

This HeadBox is attached with taper manifold.

Rotating micro adjuster handle is adjusting the lip shape is the key to CD basis weight. The limitation for this HeadBox is operating speed which is limited to 300-400 mpm & pond width upto 4 meters.

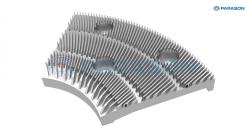

Pressurized HeadBox With German Collaboration

Its design & manufacturing process is most matured. Stock will be taken & transformed from pipeline into rectangular discharge. Rectifier rolls are used to even out flow irregularities & to create the turbulence to keep fibers deflocculated. Air cushion pressure is given from top and must be adjusted to meet the requirement of jet speed. Shower sprays are arranged to eliminate the bubbles and weak pressure pulse. Overflow volume is controlled following stock on wire. This HeadBox is also attached with taper manifold. These HeadBoxes are used for high speed application upto 1000 mpm and pond width upto 6 meters.

Control of total head and pond level

Mainly controls the pond level and slice jet speed. The slice jet speed is controlled by total head. At the same time, total head depends on pond level and air pressure. Using DCS and QCS, the whole system is runs reliable and easy to control precisely by the system.

Accujet High Turbulence HeadBox With German Collaboration

CD Basis weight Control System makes use of low frequency pulse adjusting dilution pump to feed white water in the same pressure condition. The dilution valves will respond to the signals from the dry end scanner.

In high basis weight areas the valves will open up further automatic, diluting the HeadBox stock in that zone. Oppositely, in low basis weight areas the valves will close a little automatic. Adjusting the location CD basis weight and improving the CD basis weight of the whole sheet.

Parason HeadBox System Features

Better energy savings in CDT/Octopus

Facilitate fast grade changes

Air pressurized HeadBox ensure uniform velocity condition

Micro finished inner surface.

Micro travel adjustable lip opening

Innovative shower for foam cleaning

Easily accessible inside area to insure effective cleaning